Major Capability Acquisition

Acquisition Categories (ACATs)

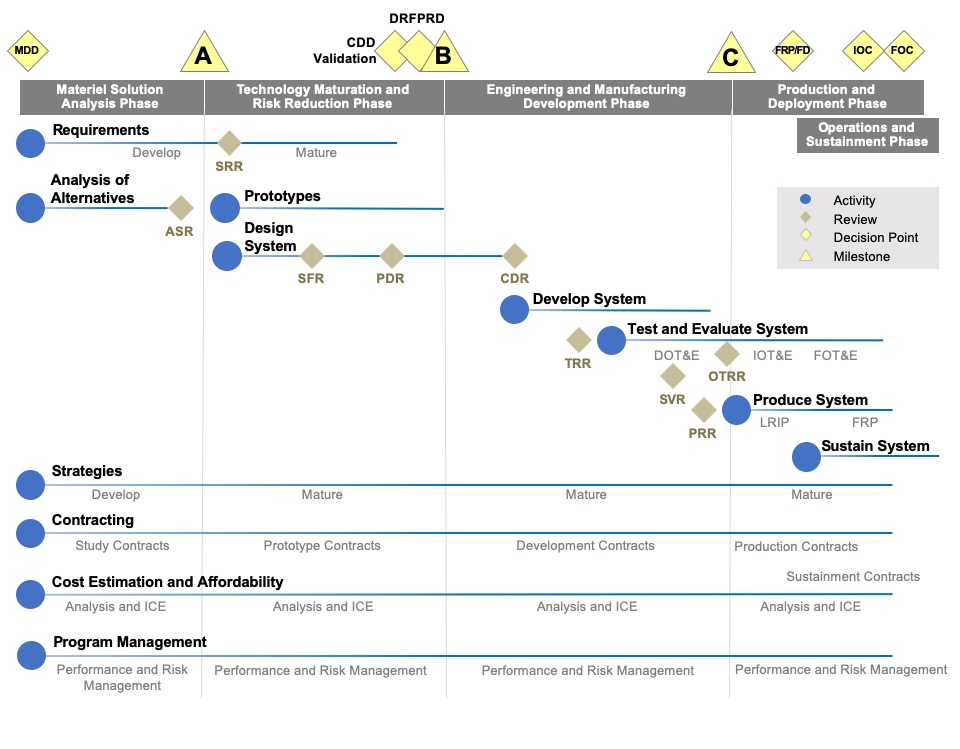

Activities Across Phases

Technical Reviews

Develop Strategies

Program Management

Cost Estimation/Affordability

MDD

MSA PHASE

Develop Requirements

Analysis of Alternatives

Study Contracts

Milestone A

TMRR PHASE

Mature Requirements

Prototype Contracts

Prototyping

Develop Preliminary Design

CDD Validation

Dev RFP Release Decision

Milestone B

EMD PHASE

Development Contracts

Complete System Design

Develop System

Developmental Testing

Milestone C

P&D PHASE

Production Contracts

Low Rate Initial Production

Operational Testing

FRP Decision

Full Rate Production/Deployment

O&S PHASE

Sustainment Contracts

Sustain System

IOC/FOC

Develop System

Draft new language for AAF

The previous activity (Complete System Design) culminates in a Critical Design Review (CDR), which aims to establish an initial product baseline and confirm that the system’s functions and capabilities satisfy the program’s requirements. That baseline design serves as the primary guidance for developing the initial system.

The contractor now uses the CDR-approved design to produce initial test articles to be used in Developmental Testing. These articles should be representative samples and/or prototypes which accurately represent the planned design. However, developmental test articles should also be inexpensive and flexible enough to be modified in response to initial test results. Developmental tests are likely to uncover opportunities to modify and improve the design, so artifacts produced during this activity should be built with thrift and adaptability in mind.

Realization

Reference Source: DAG Ch 3-4.2.4 Implementation Process

Realization is the process of building the system elements using specified materials and fabrication and production tools/procedures identified during design. Early fabrication and production planning is critical for the successful realization and delivery of the needed capability. System elements are built to the product baseline and should meet quality standards. Realization activities may include:

- Obtaining or acquiring access to materials and tools required to build system elements.

- Obtaining external system elements as applicable.

- Building system elements in accordance with implementation procedures, tolerances and applicable ESOH, security, and privacy.

- Determining system elements functionality against specified product quality characteristics.

- Document fabrication and production issues and associated corrective actions.

- Delivering implemented system elements for integration and verification.

The output of the Implementation process is the physical system elements as identified in the product baseline, including fabrication and production methods.