Tech2PEO PEO Engagement Guide

MITRE Tech2PEO Initial Program Executive Office (PEO) Engagement Guidance

1.0 About Initial PEO Engagement Guidance

This document is going to serve as the basis for advising S&T teams how to best prepare for initial contact with a program office. Specifically, S&T teams (both gov’t and industry led teams), will do research to find the ideal acquisition program transition partners to help move their capability from R&D into procurement.

2.0 How to Use PEO Engagement Guidance

Use this guidance to prepare for your first engagement with potential acquisition transition stakeholders. Much of the guidance correlates with the TMaF readiness level activities. So, it is crucial that you first conduct a self-assessment of your project’s transition readiness to understand what transition-related items you still need to accomplish and ensure they are scheduled and resourced in your S&T project plan.

3.0 Acquisition Team Functional Stakeholder Perspectives

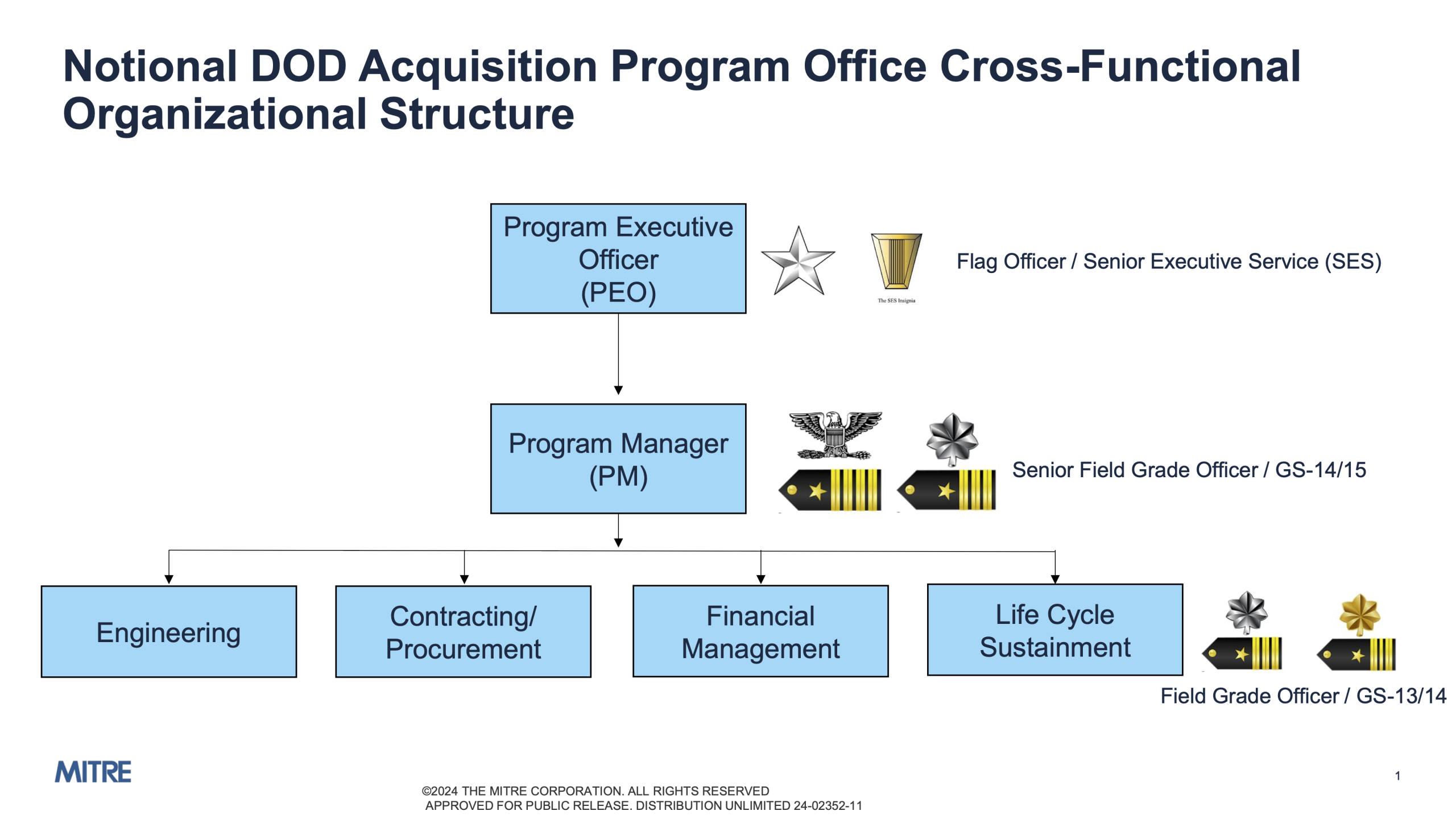

Before contacting a PEO, understand the acquisition program office stakeholders. A program office consists of cross-functional team members. A notional program office structure is below, showing the Program Executive Officer as the senior leader who has a portfolio of acquisitions programs each led by a Program Manager (PM). Working with the PMs to codevelop and execute the acquisition program are the Engineers, Contracting Officers, Financial Managers and Logisticians. This cross-functional team is typically referred to as, “the program office.” Your goal is to find the right program offices and contact the PM and/or Chief Engineer to discuss potential transition pathways from S&T to procurement, which require approval to be added to both the program’s technical and acquisition baselines.

When you meet with the program office for the first time, the PM will most likely bring representatives from the engineering, finance, and contracting functional teams. There is also a potential that the program office has a Warfighter Liaison whose mission is to assist the acquisition ecosystem with aligning the program to warfighter needs. That Liaison may also attend the meeting.

Each of these individuals will look through their respective functional roles to understand how your technology may align to the program. Sections 3.1 to 3.5 of this guidance help you understand their perspectives and the potential questions they may ask to best understand the opportunities and risks associated with integrating your project into their acquisition program.

At first glance, the listed areas of interest and questions may seem arduous, overwhelming, and even repetitive. There is no expectation that you, as the S&T team with limited DoD Defense Acquisition System (DAS) experience, limited time, and limited resources, should understand, let alone have all the answers to these questions for the first meeting. In fact, many of them are self-reflecting questions that the program office team will need to answer if your project is selected for transition into their portfolio.

For the first meeting, keep the discussion high level – tell your technology’s story, share what you have done to date, what your way ahead plan is, and why you think this is the right program office transition partnership to deliver your technology to the warfighter.

3.1 The Program Manager (PM)

As defined in the DAU Glossary, the PM is the designated individual with responsibility for and authority to accomplish program objectives for development, production, and sustainment to meet the user’s operational needs. The PM shall be accountable for credible cost, schedule, and performance reporting to the Milestone Decision Authority (MDA).i

3.1.1 What the S&T Team Should Bring to the First Meeting for the PM

- Clear Technology Description: A concise explanation of the technology, its purpose, and capabilities, as well as target users.

- Requirements Alignment: A summary of the technology’s alignment to operational requirements and/or the acquisition program explaining why this program office is the right transition partner.

- Operational Use Cases: Examples or scenarios showing how the technology addresses mission gaps or enhances capabilities.

- Warfighter Engagement: Examples of Warfighter participation in the S&T development, testing, experimentation, and/or exercises.

- Testing and Validation Results: Any available performance data from testing, demonstrations, experimentation, and/or exercise participation.

- Current Transition Readiness Status: Documentation of the technology’s current TMaF transition readiness level.

- Transition Readiness Roadmap: A visual or written roadmap outlining steps, timelines, milestones, and dependencies to mature TMaF levels.

- Integration Plan: A high-level explanation of how the technology fits into existing systems and operational frameworks.

- Initial Transition Strategy: List of key considerations for milestones, funding, and stakeholder engagement for moving the technology from S&T into procurement.

- Cost Estimates: Rough estimates for development and integration.

- Risk Identification: A summary of key technical, schedule, and cost risks (bonus point for proposed mitigation strategies).

- Sustainment: Initial thoughts on training, logistics, and maintenance.

3.1.2 PM Key Areas of Interest

- Requirements: Documentation about what the capability needs to do.

- Warfighter: Understand who we are acquiring the capability for.

- Program Maturity: Assessing maturity of the various aspects of the program.

- Cost/Schedule: Identify how much time and money we’ll commit.

- Risks: Assessing likelihood and impact of bad things happening. Identifying technical, schedule, and cost risks and ensuring mitigation strategies are in place.

- Alignment with Program Goals: Ensuring the technology supports the program’s mission objectives and operational requirements.

- Cost and Budget Impact: Understanding the financial implications of adopting the technology, including development, integration, and sustainment costs.

- Schedule and Timelines: Assessing whether the technology can be integrated within the program’s schedule and milestones.

- Testing and Validation: Ensuring the technology has been rigorously tested and validated for operational use.

- Integration Feasibility: Evaluating how the technology fits into the program’s existing systems and architecture.

- Stakeholder Buy-In: Ensuring warfighters, senior leadership, and other stakeholders support the technology’s adoption.

- Scalability and Future Growth: Assessing whether the technology can evolve to meet future mission requirements.

- Transition Strategy: Ensuring a clear plan exists for moving the technology from development to acquisition and deployment.

- Sustainment and Lifecycle Support: Understanding long-term sustainment requirements, including maintenance, training, and logistics.

3.1.3 Potential Initial PM Questions

- Do you have a plan for transitioning this technology from development to acquisition? Are there clear milestones, funding mechanisms, and stakeholder engagement strategies in place?

- Who is your sponsor? Do you have any letters of support?

- What requirement(s) does your capability address? Where / how are those requirement(s) documented?

- Describe the mission capability gap and/or opportunities?

- What timeline are you working towards?

- How does this technology align with the program’s mission objectives and address current operational gaps?

- How is this going to impact my current project?

- What does the risk profile look like?

- What risks are you introducing to the project’s cost/schedule/performance?

- How big is the integration effort?

- What is the current Technology Readiness Level (TRL), and what steps are required to mature the technology for acquisition and deployment?

- Do you have cost estimates for development and integration?

- What testing and validation have been conducted to ensure the technology performs as expected in lab and operational environments?

- Is this technology scalable or adaptable to future mission requirements? Can it be upgraded or expanded without significant redesigns?

- Have you considered a pathway for transitioning this technology into the program?

3.2 The Chief Engineer (CE) and/or Innovation Officer

The Chief Engineer serves as the technical authority for the acquisition program office, responsible for ensuring that new technologies meet operational needs, integrate effectively with existing systems, and comply with all relevant standards and regulations. During meetings with S&T teams, the Chief Engineer will be looking for clear evidence of technical maturity, validated performance, and thoughtful consideration of risks, safety, and sustainment. They will expect the S&T team to demonstrate a deep understanding of their technology’s capabilities, limitations, and integration requirements, as well as readiness to address compliance, security, and lifecycle support. Ultimately, the Chief Engineer’s goal is to assess whether the proposed solution can be reliably transitioned into the larger program and deliver measurable benefits to the mission.

3.2.1 What the S&T Team Should Bring to the First Meeting for the CE

- Data, reports, or summaries of any testing, evaluations, or experiments conducted to validate the technology’s performance in relevant environments.

- Preliminary information on how the project technology can integrate with existing systems, platforms, and infrastructure, as well as sustainment requirements (e.g., training, maintenance, logistics).

- A technical expert who can speak to the inner workings of the design, implementation, and testing already performed.

3.2.2 CE Key Areas of Interest

- System compatibility and integration.

- Technical maturity and readiness.

- Performance and Mission Effectiveness.

- Risk Management.

- Test and Validation.

- Compliance with standards/regulations.

- Program Protection and Supply Chain.

- Cyber Security.

- Scalability

- Documentation and Configuration Management.

- Spectrum Usage and Susceptibility to Electromagnetic Interference (EMI).

- System Safety.

- Survivability.

- Sustainability.

3.2.3 Potential Initial CE Questions

- (Technology Overview) What is the core technology of your prototype?

(Technology Overview) How does it work?

(Technology Overview) What performance have you achieved so far?

(Technology Overview) What improvements or changes are planned?

(Testing & Validation) What testing, exercises, or experiments have you conducted? Who participated?

(Testing & Validation) What models or simulations exist? Have they been validated? By whom?

(Testing & Validation) What is the current Technology Readiness Level (TRL)? What testing supports this assessment?

(Manufacturing & Production) How many prototypes have you built? Are they identical or improved versions?

(Manufacturing & Production) Have you completed a production run? If so, how large and what processes were required?

(Manufacturing & Production) Were any special tools or processes needed for manufacturing?

(Integration & System Context) What system activities or functions are allocated to your technology? What do other systems or performers do?

(Integration & System Context) Have you developed a context diagram or similar documentation?

(Integration & System Context) What measurable benefits does your technology provide compared to existing solutions?

(Integration & System Context) What integration challenges do you anticipate?

(Compliance & Regulatory) Does your technology comply with relevant military standards (MIL-STDs), cybersecurity, and environmental regulations?

(Compliance & Regulatory) Are there any compliance gaps to address?

(Compliance & Regulatory) If applicable, does your technology have required frequency licenses (FCC, DD1494, ITU)? What is the approval stage?

(Compliance & Regulatory) Has your technology undergone legal review for compliance with laws of armed conflict or other US codes?

(Risk & Trade Studies) What are the key technical, schedule, and cost risks? What mitigation strategies are in place?

(Risk & Trade Studies) Have you performed any cost-performance trade studies?

(Security & Protection) How is intellectual property protected against reverse engineering?

(Security & Protection) What cybersecurity measures and testing have been implemented? Any vulnerabilities or mitigations?

(Security & Protection) How is sensitive information and customer privacy protected?

(Security & Protection) Is physical security in place at your facilities?

(Safety & Survivability) Has your technology undergone safety analysis (electrical, fire, structural, airworthiness, etc.)? What hazards and mitigations were identified?

(Safety & Survivability) Has it been tested for survivability against ballistics, explosives, or electromagnetic interference?

(Safety & Survivability) Has risk management been applied to identified hazards?

(Environmental & Operational Testing) Has your technology been tested for environmental factors (shock, vibration, moisture, temperature, weather, geography)?

(Environmental & Operational Testing) How does performance vary under different conditions?

(Sustainment & Maintenance) Have you performed failure mode and effects analysis (FMECA)? What are the main failure risks and mitigations?

(Sustainment & Maintenance) What parts are replaceable (LRUs)? Which require special training or tools?

(Sustainment & Maintenance) What is the reliability and failure rate of key components?

(Sustainment & Maintenance) Are multiple vendors available for critical parts? Has cross-vendor performance been verified?

(Sustainment & Maintenance) What sustainment metrics do you collect, and over what period?

(Training & Documentation) How long does it take to train operators and maintainers?

(Training & Documentation) Is there a training course with defined learning objectives and measurable outcomes?

(Training & Documentation) Is there documentation for version control and change impact analysis?

(Facilities & Logistics) Are special facilities required for operation, maintenance, or storage?

(Facilities & Logistics) What are the size, weight, power, and cooling requirements?

(Facilities & Logistics) Is standardized packaging available? Can the technology be transported using commercial means?

(Installation & Calibration) How is the technology installed and configured at the customer site?

(Installation & Calibration) Are calibrations required? What equipment and accuracy are needed?

(Interfaces & Standards) What physical, messaging, and data standards are used for communication with external systems?

(Interfaces & Standards) Are there anticipated integration challenges with current system architecture?

(Human Factors) What functions require human interaction?

(Human Factors) Has a task analysis been performed to ensure safe and optimized interfaces?

3.3 The Financial Manager

3.3.1 What the S&T Team Should Bring to the First Meeting for the FM

- Understanding of the developmental sunk cost broken out by labor, material by life cycle, to discuss cost drivers of integration into a program such as:

- Prototype cost, number of units.

- Test requirements.

- Lead-time for parts and assembly.

- Detailed cost estimates for development, integration, sustainment, and lifecycle support.

- Breakdown of costs by phase (e.g., R&D, production, sustainment) and funding sources (e.g., RDT&E, procurement, O&M).

- Historical cost data or analogous program comparisons to validate cost estimates.

- Risk assessment for cost overruns and mitigation strategies.

- Return on Investment (ROI) analysis, including operational benefits versus cost.

- Funding requirements and timelines, including projected annual expenditures.

- Cost drivers and assumptions used in the cost estimate (e.g., labor, materials, testing).

- Sustainment cost projections, including maintenance, logistics, and training.

- Transition strategy with financial implications for moving the technology into acquisition.

- Information on potential cost savings or efficiencies compared to existing solutions.

3.3.2 FM Key Areas of Interest

- Affordability for schedule impact, test and integration cost (to assess PPBE impacts for Program Office).

- Lifecycle impacts on training and implementation, logistics, O&M (collect the inputs to update budget estimates for POM inputs).

- Align maturity with strategy to field – (assess options to mature technology with users through incremental fielding – and align to an acquisition path like MTA).

- Cost Estimates: Ensuring the cost estimates are accurate, well-documented, and based on realistic assumptions.

- Funding Sources: Understanding available funding streams and whether the technology fits within the program’s budget.

- Lifecycle Costs: Evaluating the total cost of ownership, including development, production, sustainment, and disposal.

- Cost Risks: Identifying potential cost overruns and ensuring mitigation strategies are in place.

- Affordability: Assessing whether the technology is affordable within the program’s financial constraints.

- Cost Drivers: Understanding the primary factors influencing costs and opportunities to reduce them.

- Return on Investment (ROI): Evaluating the operational benefits of the technology relative to its cost.

- Budget Alignment: Ensuring the technology’s funding requirements align with the program’s budget cycle and priorities.

- Financial Transparency: Ensuring cost estimates are transparent and traceable to credible data sources.

- Compliance: Verifying adherence to financial regulations, policies, and reporting requirements.

3.3.3 Potential Initial FM Questions

- Describe vendor and market conditions for your technology?

- Have you conducted a Return on Investment (ROI) analysis to demonstrate the operational benefits relative to the cost?

- Can you discuss the key elements to understand – Cost Benefits and ROI

- Describe the quantifiable benefits of integrating and using the technology. (cost savings, efficiency gains)

- Describe the qualitative benefits of integrating and using the technology. improved user experience, compliance

- What are the estimated costs for development, integration, and sustainment of this technology? How does it compare to alternative solutions in terms of affordability?

- What are the primary cost drivers for this technology, and are there opportunities to reduce costs or improve efficiency?

- What assumptions were used in the cost estimate, and how were they validated?

- Are there any sustainment cost considerations, such as maintenance, logistics, or training, that could impact long-term affordability?

- How does the total lifecycle cost of this technology compare to existing solutions or alternatives?

- What is the projected annual funding requirement for this technology, and how does it align with the program’s budget cycle?

- Have you considered the costs for development, integration, sustainment, and lifecycle support, and how these estimates were derived?

- What funding sources or mechanisms are available to support this technology, and how do they align with the program’s budget?

- What risks have been identified for cost overruns, and what mitigation strategies are in place to address them?

3.4 The Contracting Officer (CO)

The CO (or KO) is the person with the authority to enter into, administer, and/or terminate contracts. COs hold a warrant that allows them to negotiate on behalf of the government and are the only government officials authorized to bind the federal government to a contract. COs advise programs on business strategies (e.g., contract vehicles, contract type/s, data rights requirements) best suited to satisfy the program’s requirements and provide capability to the end user/warfighter.

3.4.1 What the S&T Team Should Bring to the First Meeting for the CO

- A clear description of the technology, including its purpose, capabilities, and operational benefits.

- Information on custom development or a modified COTS solution. If modified COTS, be prepared to discuss other potential solutions in the marketplace and how/why this solution was selected.

- Technology Readiness Level (TRL) and a notional roadmap for maturing the technology to acquisition readiness.

- Initial cost estimates for development, integration, sustainment, and lifecycle support.

- Thoughts on potential contracting strategies (e.g., Other Transaction Authority (OTA), FAR-based contracts)

- Identification of potential funding sources and mechanisms (e.g., RDT&E funding DER, APFIT funds, program office budgets).

- Documentation of any prior testing, validation, and performance results.

- Initial risk assessment, including technical, schedule, and cost risks, along with mitigation strategies.

- Information on any intellectual property (IP) rights, patents, and licensing agreements that may be needed or are customary in the commercial marketplace, if applicable.

- A plan to comply with regulatory requirements, including cybersecurity, environmental, and MIL-STDs.

- A plan for industry engagement or market research, if applicable.

3.4.2 CO Key Areas of Interest for Discussion

This information will be needed to inform future transition efforts. Specific details are not necessary for the initial meeting.

- Contracting Strategy: Selecting the best contracting mechanism (e.g., FAR contract OT agreement) and contract type (e.g., fixed-price, cost-plus, hybrid) to acquire the technology

- Cost and Funding: Understanding cost estimates, funding sources, and affordability within the program’s budget.

- Data Rights and Intellectual Property (IP): Ensuring data rights and IP are clearly defined and do not hinder future use or sustainment.

- Regulatory Compliance: Verifying adherence to acquisition policies, cybersecurity requirements, and environmental regulations.

- Market Research: Assessing whether industry engagement or competition is required to identify potential vendors or solutions.

- Risk Management: Evaluating risks related to cost, schedule, and performance, and ensuring they are accounted for in the contracting strategy.

- Performance Metrics: Ensuring clear deliverables, milestones, and metrics are defined for contract execution.

- Small Business Participation: Determining if the technology or contracting strategy supports small business participation goals.

- Transition Plan: Understanding how the technology will move from development to acquisition and deployment.

3.4.3 Potential Initial CO Questions

- Is there an estimated cost for development, integration, and sustainment of this technology? If so, how was this estimate derived? If not, this will be needed for transition.

- Have you identified any funding sources or mechanisms that may be available to support this technology’s transition into an acquisition program?

- What contracting strategy are you considering for the S&T development? For example, leveraging a competitive Prototype OT provides a path to a follow-on OT or FAR contract without the need to recompete.

- Are there any data rights or intellectual property (IP) considerations, such as patents or licensing agreements, that need to be addressed?

- Does this technology comply with all relevant acquisition regulations, cybersecurity requirements, and environmental standards? What is the strategy to address compliance with relevant regulations (e.g., cybersecurity, environmental)

- What risks have been identified for cost, schedule, and performance, and how will these be mitigated in the contracting process?

- Have you done any industry engagement or market research to identify potential vendors or solutions for this technology? If so, what? If not, are there any plans to do so?

- Will there be any key deliverables, milestones, and performance metrics that should be included in the contract to ensure accountability? If known, what are they?

- Does this technology support small business participation goals, or are there opportunities for subcontracting with small businesses? Is this technology available from small or innovative firms?

- What is the plan for transitioning this technology from development to acquisition?

3.5 The Product Support Manager (PSM)

As the PM’s key leader for sustainment planning and life cycle management, the Product Support Manager (PSM) has primary responsibility for implementing many of the actions, processes, and procedures for product support, from concept through disposal and including the development of a Life Cycle Support Plan (LCSP). The Product Support Manager, with assistance from the implementing command, develops and implements a comprehensive product support strategy for each applicable program.

3.5.1 What the S&T Team Should Bring to the First Meeting for the PSM

- Conceptualized Product Support Plan: a short overview of how it is expected for the technology to be supported throughout its lifecycle.

- Anticipated length of the technology’s life cycle: provide the rough order life span for the technology to compare/contrast against other systems or technologies the new technology may be interfacing with.

- Expected transition of the technology with MVP, IOC and FOC estimates helps with planning and preparation for testing and fielding.

- Ways and methods the technology could be matured, updated, and/or modified: provides insight as to the types of skills required to maintain the relevancy of the new technology over time.

- Known data elements created by and required by the technology significantly helps with detailed data planning for both data created as well as other date and systems that ingest or use data from the new technology.

- Acknowledgement of likely key stakeholders that would make long-term support and sustainment decisions: lays the groundwork for the offices and organizations that will require an input for long-term sustainment planning.

- Initial reliability, maintainability, and availability analyses and estimates: RM&A estimates directly impact resourcing (personnel and spare parts if a system as well as training.

- Training requirements and artifacts: significantly impacts O&S costs and is impacted by RM&A analyses as well as how much contractor support is expected for the new technology.

- Maintenance requirements for the technology: closely aligned with training, clarification in terms of what entities (govt, contractor, hybrid) complete which maintenance actions on the technology is vital in developing the right resourcing.

- Possible courses of action for consideration in terms of organic support vs contractor support vs hybrid support: huge O&S driver that is frequently very complex.

3.5.2 PSM Key Items of Interest

- Explanation of what the technology is and how it is expected to be used: clarifies what current resources may be impacted and which need to be expanded to support the new technology.

- Explanation of how system users will operate the technology: provides background that helps with resource planning.

- Understanding of the conceptualized training tract for users: clarifies a vital factor for future sustainment of the technology.

- Explanation of possible policy and guideline challenges to the implementation of the technology (ATO, ATC, environmental, safety, etc.): identifies if there is a need for waivers or changes to tactics, techniques and procedures.

- Discussion about possible integration and interoperability: clarifies if there are second- or third-order effects of implementing new technology that must be linked or connected to legacy systems.

- Understanding of resources (i.e., people) required to operate, maintain, and sustain the technology: assesses a big piece of the O&S cost pie.

- Clarification in terms of host technology requirements like support equipment, test equipment, facilities, etc.: reduces future fielding and implementation challenges.

- Clarification of level of effort to maintain and sustain the technology: evaluates what it takes to use the technology in an operational environment.

- Identifying what data are required, what data are generated, and who owns the data: evaluates a key support element that later, if misunderstood can lead to significant O&S cost increases.

- Test concepts and requirements for maintenance and sustainment of the technology: provides insight as to how much life cycle sustainment SMEs and functional experts will be involved in the test process with an expectation their involvement will improve long-term sustainment.

- Expected transition timelines and laydown of technology: key elements required to assess the planning factors for all sustainment activities.

- Exploration of potential impacts for fielding of other systems in use that may need to be modified or adjusted to host the new technology: assess the second- and third-order effects on other systems that include costs that result from implementing the new technology.

- Cost estimates to do the above: helps evaluate the magnitude of the ask for numerous budget drills and is a key metric when comparing the various COAs.

3.5.3 Potential Initial PSM Questions

- Transition timelines and fielding – is there an initial integrated master schedule?

- Is there a listing of known software needs and requirements? Firmware, other software products with needs for specific versions?

- Is there a listing of known hardware needs and requirements?

- Is there a listing of known support equipment and test equipment needs and requirements?

- Are there known facility requirements or needs? Temperature control? Humidity control? Material handling equipment?

- How much and how long is the expected training for maintenance and sustainment of the technology?

- How involved with the maintenance and support teams be during test events?

- How easily can the technology be updated, modified, or decommissioned?

- Who owns the data? Who controls use of the technology (NOFORN, use with allies, etc.)?

- What are expected O&S costs and what are they for?

- Is there expected to be a long-term need for continual contractor support (i.e., field service reps) or can the technology eventually be fully transitioned to the government?

- Is there an opportunity for a live demonstration of the technology and capability for the sustainment planning community as well as end users (operators, maintainers, sustainers, etc.)?

3.6 The Warfighter Liaison

3.6.1 What the S&T Team Should Bring to the First Meeting for the Warfighter Liaison

- A presentation that explains the technology in simple, non-technical terms, focusing on its purpose, capabilities, and potential benefits to the warfighter

- A physical prototype, a virtual simulation, or a video demonstration of the technology in action

- Specific examples or scenarios showing how the technology can be applied in the warfighter’s mission environment (include diagrams, charts, or vignettes to illustrate these use cases)

- A plan for how the S&T team will incorporate warfighter feedback into the development process, including opportunities for hands-on testing, user evaluations, and iterative improvements

3.6.2 Warfighter Liaison Key Areas of Interest

- Operational Relevance and Mission Fit

- Maturity and Readiness Level

- Integration and Interoperability

- Sustainment and Lifecycle Support

- Testing, Validation, and Feedback

3.6.3 Potential Initial Warfighter Liaison Questions

- How does this technology directly address current operational gaps or enhance mission effectiveness in real-world scenarios? Can you provide examples or use cases that demonstrate its value in the field? (Purpose: This question ensures the technology aligns with mission needs and validates its relevance to warfighter requirements. It helps the warfighter understand how the solution fits into their operational environment.)

- What is the current Technology Readiness Level (TRL) of this solution, and what steps are needed to reach a TRL suitable for acquisition and deployment? Are there any critical risks or dependencies? (Purpose: Understanding the TRL helps assess how close the technology is to being operationally viable and identifies potential hurdles in transitioning from development to acquisition.)

- How does this technology integrate with existing systems, platforms, and infrastructure? Are there compatibility issues or additional requirements for successful deployment? (Purpose: Warfighters need to know if the solution can seamlessly integrate into their current systems or if significant modifications are required, which could impact cost and timelines.)

- What are the sustainment requirements for this technology, including maintenance, training, and logistics? How does it impact the overall lifecycle cost compared to existing solutions? (Purpose: This question addresses long-term considerations such as maintenance, training, and cost, which are critical for acquisition decisions and operational sustainability.)

- What testing and validation have been conducted to ensure the technology performs as expected in operational environments? Is there a process for incorporating warfighter feedback into future iterations? (Purpose: This ensures the technology has been rigorously tested and validated for real-world use and highlights opportunities for warfighters to provide input to refine the solution.)

i Defense Acquisition University. (n.d.). Program manager. DAU Glossary. Retrieved October 3, 2023, from https://www.dau.edu/glossary/program-manager